|

Baoding Shunda Rubber Belts Co., Ltd

|

China Manufacturer Industry heavy duty steel cord conveyor belt

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Hebei, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.st630-6300

2.B400-3000

3.ISO, GS, CE certificate

4.Din, As, GB, Jis, Bs, Sabs standard

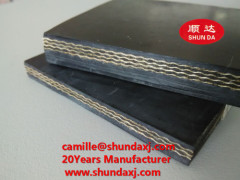

Steel Cord Conveyor Belt Description

Usage:

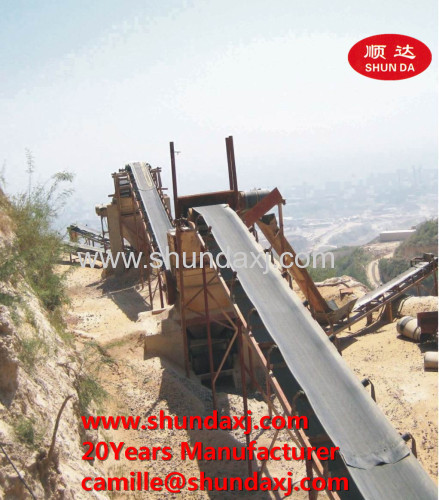

Conveying materials in coal, mine, harbour, metallurgy, power station, chemical, etc.

Our Advantage:

1. Dia of Steel cord: 3.0- 11.3

2: width: 400-2500mm

3. Thickness: 4-30mm

4. Grade: ST/S630- ST/S6300

5. General / Reinforced / Underground with safety certificate from Chinese Government.

6. Abrasion resistant & High Tensile Strength

7. ISO9001:2008, SGS, CE Certificate.

8. We already export to more than 30 countries.

9. International Standard : DIN, BS, AS , RMA, AS, JISK, SABS etc.

10. We have more than 19 years Professional production experience

Specification data sheet:

GB/T 9770-2001 standard

Belt strength(st-No.) | Cord diam.(mm) | Pitch of cord(mm) | Stand working tension(N/mm) | Standard cover thickness(mm) | Belt weigth(kg/m2) | Min. pulley diam(mm) | Cord strength(KN/piece) |

St-630 | 3.0 | 10 | 90 | 5x5 | 20 | 800 | 6.93 |

St-800 | 3.5 | 10 | 110 | 5x5 | 20.6 | 800 | 8.8 |

St-1000 | 4.0 | 12 | 140 | 6x6 | 24.7 | 800 | 13.2 |

St-1250 | 4.5 | 12 | 175 | 6x6 | 25.4 | 800 | 16.5 |

St-1600 | 5.0 | 12 | 225 | 6x6 | 26 | 1000 | 21.12 |

St-2000 | 6.0 | 12 | 285 | 8x6 | 30 | 1000 | 26.4 |

St-2500 | 7.5 | 15 | 355 | 8x6 | 32.3 | 1250 | 41.25 |

St-3150 | 8.1 | 15 | 450 | 8x8 | 35.7 | 1400 | 51.98 |

St-4000 | 9.1 | 17 | 570 | 8x8 | 37.8 | 1600 | 74.8 |

St-4500 | 9.7 | 16 | 645 | 8x8 | 38.7 | 1800 | 79.2 |

St-5000 | 10.9 | 17 | 715 | 8.5x8.5 | 41.9 | 1800 | 93.5 |

St-5400 | 11.3 | 17 | 760 | 9x9 | 43.9 | 2000 | 101 |

St-6300 | 13.0 | 17 | 887 | 10x10 | 49.4 | 2500 | 139 |

Number of steel cords :

Width(mm) | St630 | St800 | St1000 | St1250 | St1600 | St2000 | St2500 | St3150 | St4000 | St4500 | St5000 | St5400 | St6300 |

800 | 75 | 75 | 63 | 63 | 63 | 63 | 50 | 50 | |||||

1000 | 95 | 95 | 79 | 79 | 79 | 79 | 64 | 64 | 56 | 60 | 56 | 56 | 52 |

1200 | 113 | 113 | 94 | 94 | 94 | 94 | 76 | 76 | 68 | 72 | 68 | 68 | 63 |

1400 | 133 | 133 | 111 | 111 | 111 | 111 | 89 | 89 | 79 | 84 | 79 | 79 | 74 |

1600 | 151 | 151 | 126 | 126 | 126 | 126 | 101 | 101 | 91 | 96 | 91 | 91 | 85 |

1800 | - | 171 | 143 | 143 | 143 | 143 | 114 | 114 | 103 | 107 | 103 | 103 | 96 |

2000 | - | - | 159 | 159 | 159 | 159 | 128 | 114 | 114 | 120 | 114 | 114 | 107 |

2200 | - | - | - | - | - | 176 | 141 | 141 | 125 | 133 | 125 | 125 | 118 |

South African National Standard for steel cord reinforced conveyor belting: SANS 1366;2006

Australian conveyor belt standard for steel cord reinforced conveyor belting: AS1333-2000

DIN22131 standard

Type(st-No.) | ST400 | ST500 | ST630 | ST800 | ST1000 | ST1250 | ST1600 | ST1800 | ST2000 | ST2500 | ST3150 | ST3500 | ST4000 | ST4500 | ST5000 | ST5400 | ST6300 | |

Belt strength(N/mm) | 400 | 500 | 630 | 800 | 1000 | 1250 | 1600 | 1800 | 2000 | 2500 | 3150 | 3500 | 4000 | 4500 | 5000 | 5400 | 6300 | |

Min strength of steel cord (KN) | 5.3 | 5.3 | 10 | 11.5 | 13.2 | 19.2 | 26.4 | 26.4 | 26.4 | 41.2 | 52 | 57.7 | 66 | 79.2 | 93.5 | 101 | 139 | |

Max dia of steel cord(mm) | 2.5 | 2.5 | 3.3 | 3.5 | 4.1 | 4.9 | 5.6 | 5.6 | 5.6 | 7.2 | 8.1 | 8.6 | 8.9 | 9.7 | 10.9 | 11.3 | 13 | |

Cord pitch(Step distance of two steel cord)(±1.5mm) | 12 | 10 | 13.5 | 13.5 | 12 | 14 | 15 | 13 | 12 | 15 | 15 | 15 | 15 | 16 | 17 | 17 | 20 | |

Width of belt(mm) | Tolerance(mm) | Number of steel cords | ||||||||||||||||

500 | ±5 | 40 | 48 | 36 | 36 | 40 | 34 | - | - | - | - | - | - | - | - | - | - | - |

650 | ±7 | 53 | 63 | 47 | 47 | 52 | 44 | - | - | - | - | - | - | - | - | - | - | - |

800 | ±8 | 65 | 78 | 58 | 58 | 64 | 55 | 50 | 58 | 62 | 50 | 50 | 50 | - | - | - | - | - |

1000 | ±10 | 82 | 98 | 73 | 73 | 81 | 69 | 64 | 73 | 78 | 64 | 64 | 64 | 64 | 59 | 55 | 55 | 47 |

1200 | ±10 | 98 | 118 | 87 | 87 | 97 | 84 | 77 | 88 | 97 | 77 | 77 | 77 | 77 | 71 | 66 | 66 | 57 |

1400 | ±12 | 115 | 138 | 102 | 102 | 114 | 98 | 90 | 104 | 114 | 90 | 90 | 90 | 90 | 84 | 78 | 78 | 67 |

1600 | ±12 | 132 | 158 | 117 | 117 | 131 | 112 | 104 | 120 | 131 | 104 | 104 | 104 | 104 | 96 | 90 | 90 | 77 |

1800 | ±14 | 148 | 177 | 131 | 131 | 147 | 126 | 117 | 136 | 147 | 117 | 117 | 117 | 117 | 109 | 102 | 102 | 87 |

2000 | ±14 | 164 | 197 | 146 | 146 | 164 | 141 | 130 | 150 | 164 | 130 | 130 | 130 | 130 | 121 | 113 | 113 | 97 |

2200 | ±15 | - | - | 161 | 161 | 181 | 155 | 144 | 166 | 181 | 144 | 144 | 144 | 144 | 134 | 125 | 125 | 107 |

2400 | ±15 | - | - | - | 175 | 197 | 169 | 157 | 182 | 197 | 157 | 157 | 157 | 157 | 146 | 137 | 137 | 117 |

2600 | ±15 | - | - | - | - | 214 | 184 | 170 | 195 | 214 | 170 | 170 | 170 | 170 | 159 | 149 | 149 | 127 |

2800 | ±15 | - | - | - | - | 231 | 198 | 184 | 210 | 231 | 184 | 184 | 184 | 184 | 171 | 161 | 161 | 137 |

3000 | ±15 | - | - | - | - | 247 | 212 | 197 | 226 | 247 | 197 | 197 | 197 | 197 | 184 | 172 | 172 | 147 |

Thickness of belt(mm) | Tolerance(+1.0-0.5mm) | 10.5 | 10.5 | 13.5 | 13.5 | 14 | 14 | 19.5 | 19.5 | 19.5 | 25 | 26 | 26.5 | 29 | 29.5 | 33 | 33.5 | 35 |

Thickness of top rubber(mm) | 4 | 4 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 10 | 10 | 10 | 12 | 12 | 12 | 12 | 12 | |

Thickness of bottom rubber(mm) | 4 | 4 | 4 | 4 | 4 | 4 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 8 | 10 | 10 | 10 | |